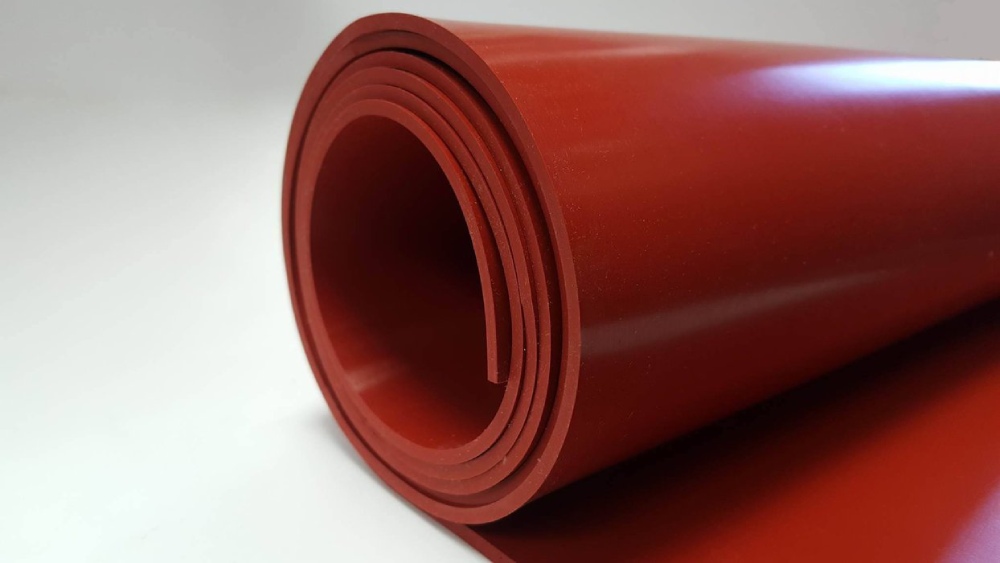

Silicone rubber is a key sealing substance in a full range of industries such as medical, aerospace, automotive, electronics and more. Due to its numerous unique and optimal attributes, silicone rubber can be desired for a number of applications.

Apple Rubber utilizes many complex technology to take full benefit of silicone sealing capacities, producing everything from easy seals into the most complex pieces. Here are the Significant Advantages of silicone rubber that You Should Think about when Choosing a sealing material:

High-Quality Sealing Material

Best known for its exceptional thermal stability, silicone rubber can withstand extremely low and high temperatures. In low-temperature conditions, silicone keeps its flexibility, making it an optimal material choice for applications in extreme temperature environments.

Along with temperature resistance, silicone additionally has resistant attributes for many other substances, including acids, bases, chemicals, oil, water and fungus. In spite of all of these resistant properties, this quality rubber is non-toxic, which makes it a reliable sealing substance for consumer goods and medical devices.

Sterilization Abilities

Silicone rubber is compatible with FDA regulations and can experience many different sterilization methods. These sterilization methods enable silicone to be qualified for use in the medical sector and also be termed a medical grade material.

Apple rubber uses silicone rubber as a leading sealing material for the medical sector, technology parts and seals for dialyzers, medical pumps, IV components, feeding devices and implant material. Employing an ISO Classified cleanroom, Apple Rubber manufactures and evaluations sterile silicone rubber seals for medical grade classification in order to be shipped out for use in the medical industry.

Extremely Versatile

Silicone is easy to customize and mildew, making it great for custom molded shapes and specific programs with particular requirements. By adjusting the chemical recipe, the seal can obtain more immunity properties, like temperature and water resistance. It can also be made see-through or some other colour imaginable, even glow in the dark green. Due to its versatility, silicone can be chosen for innovative models and testing for design engineers.

To achieve complex molded shapes, liquid silicone rubber (LSR) is used. This two-part platinum cured elastomer is injected into a mould cavity and then manufactured to a part. There are several distinct sorts of LSR chemicals offering a variety of special benefits, such as medical grade, self-lubricating, conductive, self-bonding, radio-opaque and more.

High-Performing Rubber

Silicone is known for its retention of flexibility and low compression set in extreme heat or cold. Silicone rubber is quite durable and overall, has good mechanical properties. Due to its durability, it is very reliable and can be trusted to keep up performance for a long time.

Among other advanced capabilities, silicone rubber also offers great electrical insulation, is flame repellent and contains a low chemical reactivity. These attributes are what create silicone a great sealing material for a vast assortment of applications and businesses.